Hydraulics Aidro: Hydraulic valves, manifolds, accessories, systems and specials

- Home

- Hydraulics

What we do

Hydraulic products are designed and produced to guarantee an excellent performance and to be efficient in every situation. Our products are also customized in order to find application on various settings and to meet customer requirements.

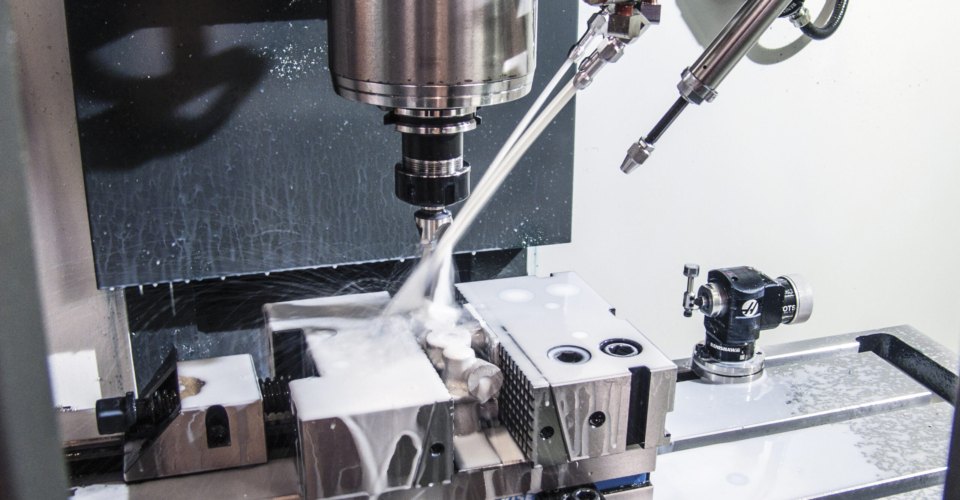

PRODUCTIONOur manufacturing process allow us to create high quality hydraulic products such as manifolds, valves and other components that feature excellent resistance and fluid power efficiency. We offer a wide range of hydraulic components for integrated solutions and for your applications. Our production and supply chain are based in Europe.

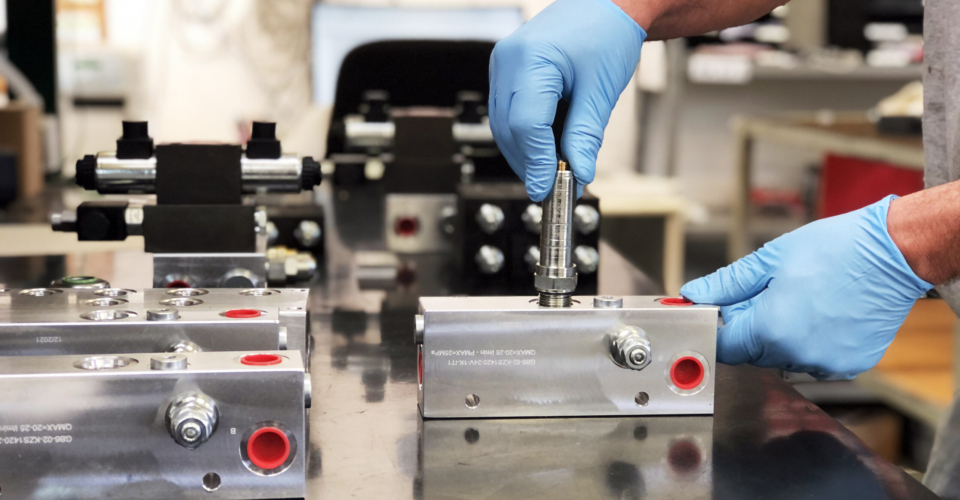

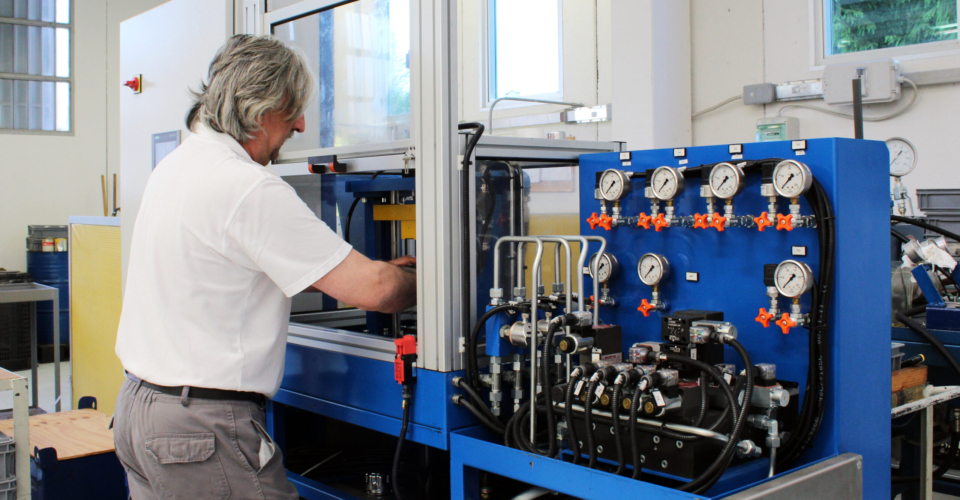

TESTINGTo guarantee the best quality we conduct various tests with test bench on pressure resistance, material, mechanical properties, dimensional and functional characteristics.

QUALITY CONTROLOur hydraulic products are realized, controlled and measured meticulously to guarantee excellent precision.

QUALIFICATION AND CERTICATIONSWe operate according to our quality management system. We are certified ISO 9001 and EN9100.

Articles and news

Our products

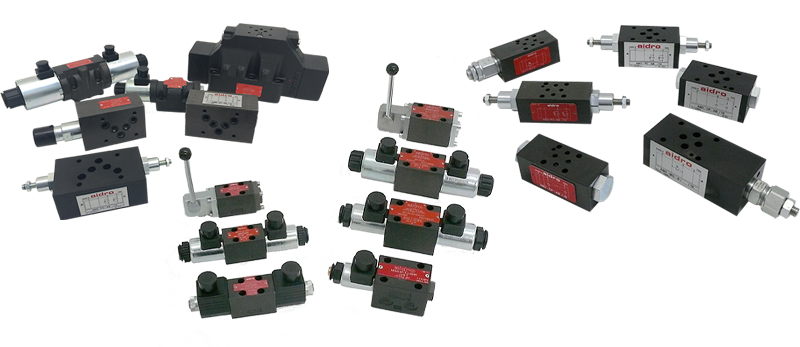

Valves

A wide range of valves suitable for the creation of complex hydraulic circuits. From Cetop components to cartridge valves for integrated solution, we can provide a complete range of components for your applications.

Most of the standard components are ready from stock and can be shipped in few days from the order. Don’t hesitate con contact our commercial service for any request

Our valves

→ Directional valves

→ Flow valves

→ Check valves

→ Pressure valves

→ Proportional valves

→ Overcenter valves

ATEX

Explosion proof valves. 15 years of experience in ATEX valves assure you a professional and accurate support for your applications in this delicate sector. We have on-off valves, proportional valves and poppet valves with certification Gas and Dust and temperature class from T5 to T6.

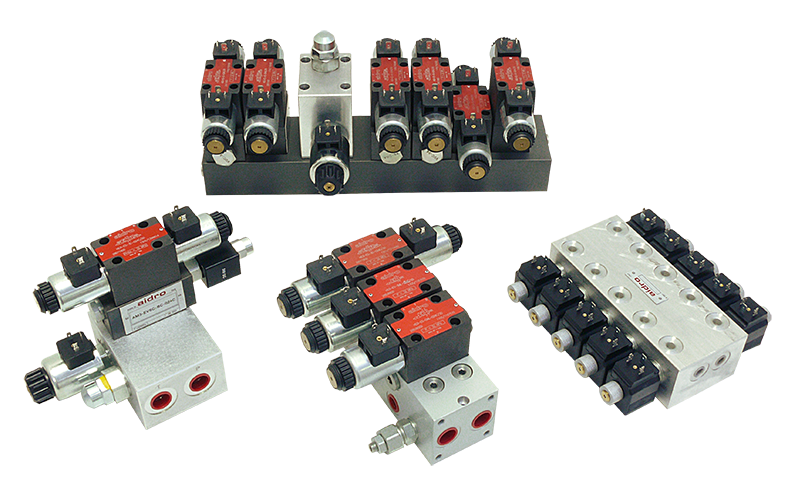

Manifolds

Manifolds of different sizes are available. We have cetop 02 (NG04) standard manifolds, NG06 and NG10 delivered from stock.

We produce also the most common in line assembly body for SAE08 and SAE10 cartidges. We design and produce also customized manifolds for all hydraulic application which requires integrated or more complex systems.

Our manifolds

→ Cetop manifolds

→ In line assebly manifolds

→ Special manifolds

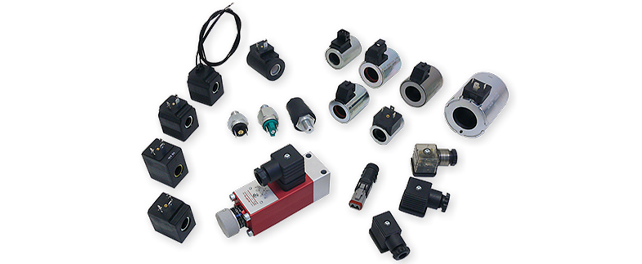

Accessories

Simple accessories are available as complement of our product range.

We can supply a widre range of connettors, different type of coils for all our products.We have also reliable pressure switches which can be installed in line or in specific cetop modules.

Our accessories

Specials

Aidro designs and produces complete systems together with our customers. We have different solutions for specific functions or applications which are normally designed using our reliable components. Don’t hesitate to contact us for jointly developing your hydraulic system.

Aidro has also many non stadard components not present in the main catalogue and produced for specific customers. Don’t hesitate to ask us for non standard valves… maybe we already have them!

Our specials

REGISTERED OFFICE

Via Camperio 9

20123 Milano (MI)

Italy

HEADQUARTERS

Via Prati Bassi 36

21020 Taino (VA)

Italy

+39 0331 960250

aidro@aidro.it

LATEST NEWS

© Copyright 2021. All Rights Reserved – Aidro s.r.l. a socio unico