Additive Manufacturing Aidro

- Home

- Additive Manufacturing

What we do

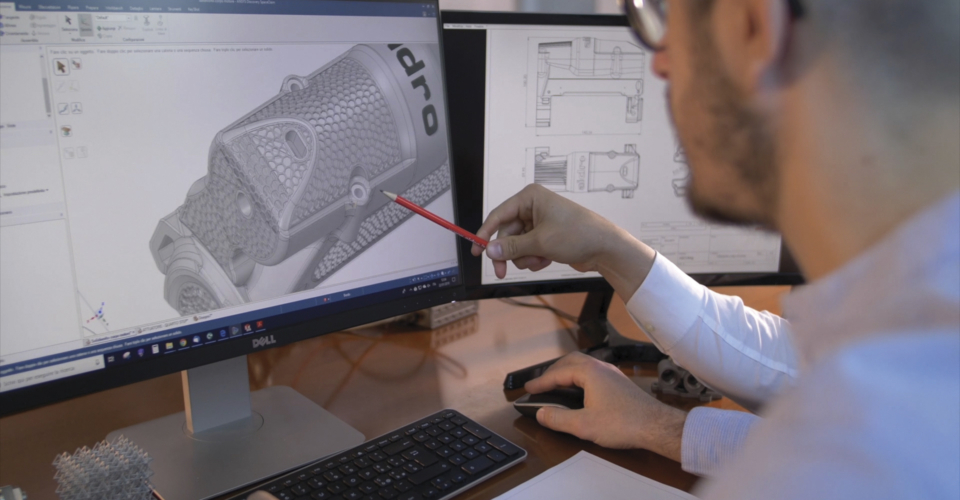

New hydraulic products with complex geometries and re-designed traditional hydraulic parts to reduce weight, save space, consolidate multiple pieces into one. FEA and reverse engineering.

PRODUCTIONWith our metal 3D printers (DMLS technology), we can create a wide range of products using high-quality metals such as Stainless Steel (AISI316L), Aluminum (Alsi10Mg), Inconel (718), Maraging steel. We use laser powder bed fusion technology that features high mechanical properties and fatigue resistance.

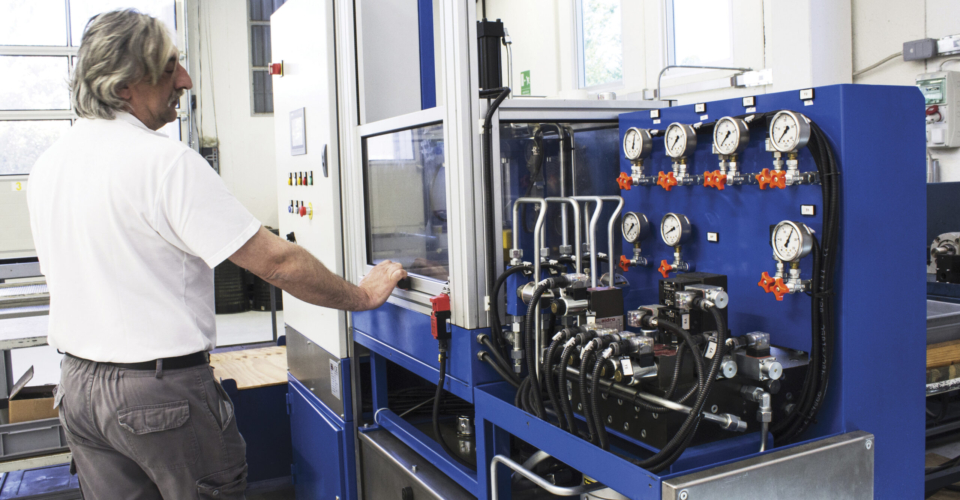

TESTINGTo guarantee the best quality we conduct various tests on pressure resistance, material, mechanical and micro-structural properties and functional characteristics.

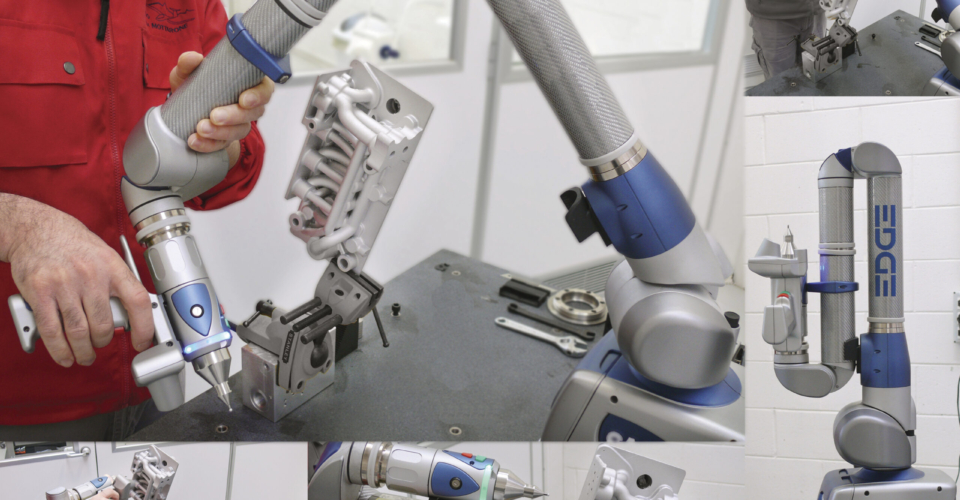

QUALITY CONTROLAdditive manufacturing products feature outstanding precision as they are designed and analyzed by dimensional control by 3D scan and reverse engineering. We normally reach achieve tolerance of ± 0.3 as build.

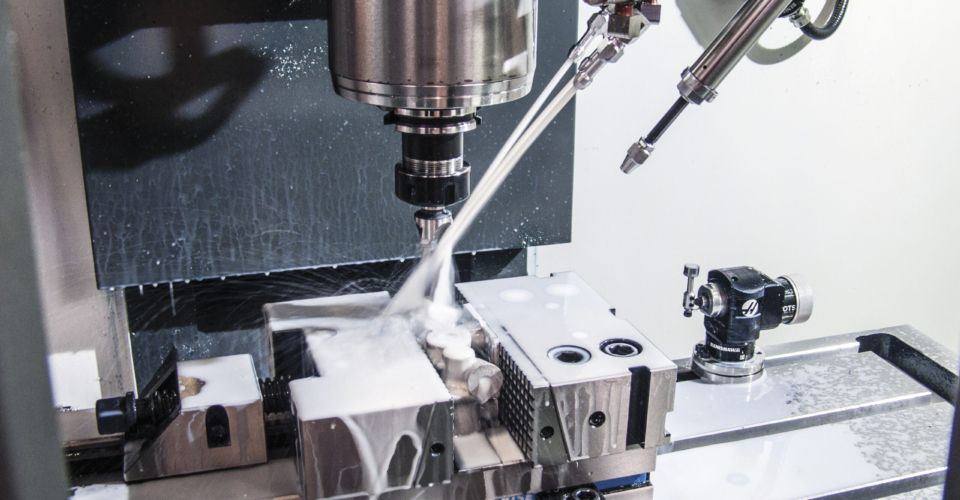

CNC AND FINISHINGWith our flexible vertical machining center, we provide the machining of cavities, surfaces and parts of the 3D printed products that require a finishing. Heat treatment of 3D metal printed parts, surface finishing, coatings and tumbling.

QUALIFICATION AND CERTICATIONSWe operate according to our quality management system and we follow the general standard of additive manufacturing (ASTM, ISO, DNV). We are certified EN9100, DNV-SE-0568 and DNV-ST-B203.

Articles and news

BJMI Project – Binder Jetting Made in Italy

BJMI Project – Binder Jetting Made in Italy Extention of DNV Additive Manufacturing facility Certificate with a new material qualified

Extention of DNV Additive Manufacturing facility Certificate with a new material qualified Aidro receives the recognition of “Environmental Sustainability Research” by AMGTA

Aidro receives the recognition of “Environmental Sustainability Research” by AMGTA Aidro presents ATILIUS Project

Aidro presents ATILIUS Project Aidro Team has achieved the Quality Management System Certificate for renewal of both EN/AS9100 and ISO9001

Aidro Team has achieved the Quality Management System Certificate for renewal of both EN/AS9100 and ISO9001

Additive Manufacturing Solution Center for Fluid Power

Aidro has introduced Additive Manufacturing to create a new generation of hydraulic components and to overcome the limits of traditional manufactured parts. The 3D printing technology allows fast lead time and better performances thanks to the optimization of the internal channels.

Using a new engineering approach and “think outside the box” mindset, Aidro can design and 3D print:

→ customized solutions with complex geometries

→ lightweight and compact hydraulic products

→ integrate multiple parts into one

→ rapid prototypes and fast spare parts

On the basis of almost 40 years of experience in hydraulics, Aidro considers additive manufacturing a good way to solve technical issues and create innovative solutions.

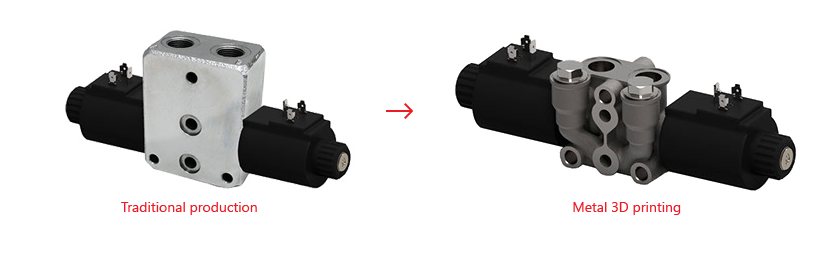

AMES Valves

CETOP 3 in Stainless Steel 316L

HD3-AMES are metal 3D printed directional control valves with innovative stainless steel 316L body and solenoid actuators with subplate mounting interface according to ISO 4401, DIN 24340 (CETOP 03). The valve body is made with Laser Powder Bed Fusion (LPBF) technology. Internal design is improved for better flow path thanks to additive manufacturing design.

Paired with plastic encapsulated coils this valve is proven to be corrosion resistant even in the harshest environments.

Main characteristics

→ Feasibility of geometric forms impossible with conventional manufacturing

→ Improved internals chambers flow path

→ Lightweight design with increased stifness with external reinforcements

CETOP 2

HD2-AMES are metal 3D printed directional control valves with innovative stainless steel 17-4PH body and solenoid actuators with subplate mounting interface according to ISO 4401, DIN 24340 (CETOP 02). The valve body is made with Binder Jetting technology. Internal design is improved for better flow path thanks to additive manufacturing design.

HD2-AMES are metal 3D printed directional control valves with innovative stainless steel 17-4PH body and solenoid actuators with subplate mounting interface according to ISO 4401, DIN 24340 (CETOP 02). The valve body is made with Binder Jetting technology. Internal design is improved for better flow path thanks to additive manufacturing design.

Main characteristics

→ Feasibility of geometric forms impossible with conventional manufacturing

→ Improved internals chambers flow path

→ Lightweight design with increased stifness with external reinforcements

Pneumatic

New pneumatic valve in stainless steel 316L suitable for explosion proof environments is available with CETOP03 size.

The lightweight body valve is designed for Additive Manufacturing.

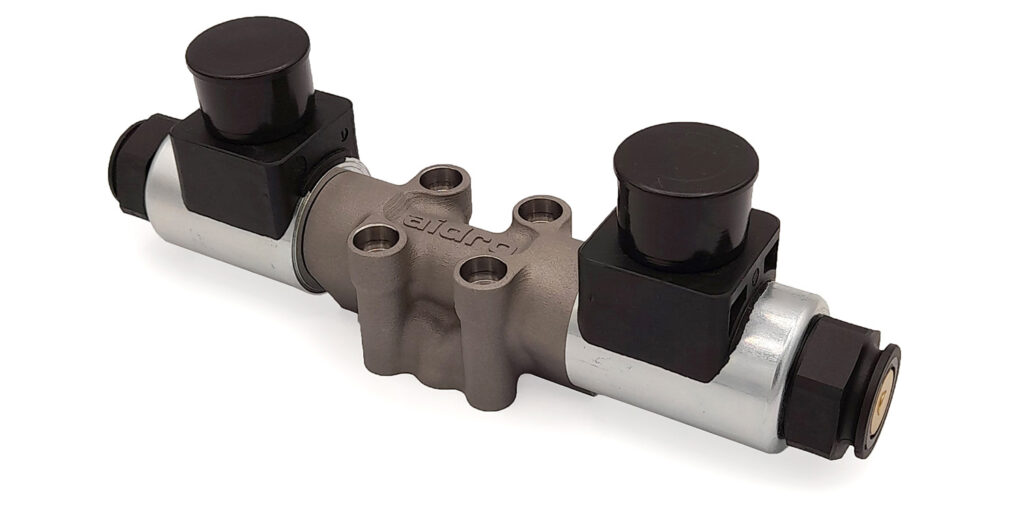

Bankable

HDF-AMES are metal 3D printed bankable directional control valves. The body is made in Stainless Steel 316L. Internal flow path is optimized thanks to the Additive Manufacturing technology and allows a strong reduction in pressure drops among with a never seen before weight and volume reduction. Both body and actuation are made with stainless steel, suitable for the harshest environments. The system can also be printed as a whole part avoiding assembly problems or eventual leaks between working sections.

A wide range of optional elements are available and can be integrated within the system. Working sections are available with ON/OFF or proportional control and with parallel or series circuit.

Main characteristics

→ Flow rate up to 60 l/min and 350 bar

→ Weight reduction up to 55%

→ Wide variety of spools, including asymmetrical proportional spools

→ Optional modules can be assembled with the system or directly integrated in the printing 350 bar

→ Bodies can be custom made integrating any specific customer’s functions

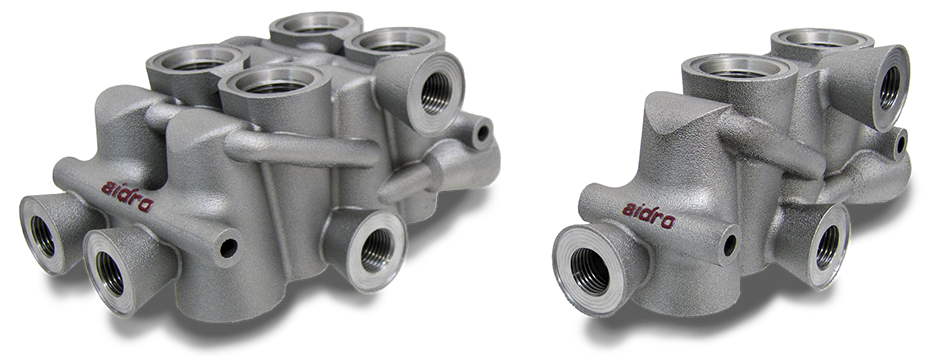

Hydraulic Manifold

"UGO" Manifold

This hydraulic manifold is used in Agricultural Machinery to control cylinders and motors.

3D printing advantages

→ Half weight and size

→ Reduction of components (from 194 to 42)

→ Optimized internal channels

→ SS316L material combines excellent strenght, high ductility, and high resistance to corrosion and pitting

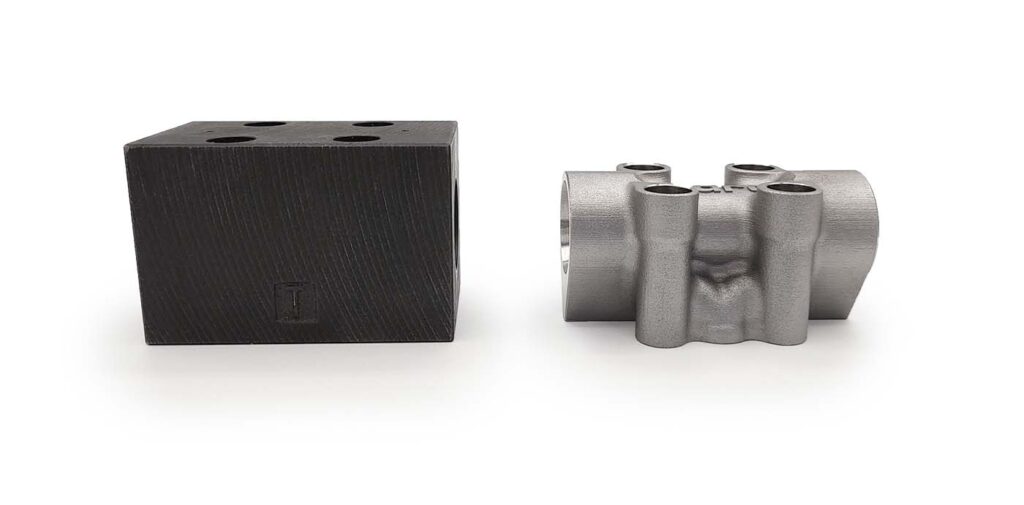

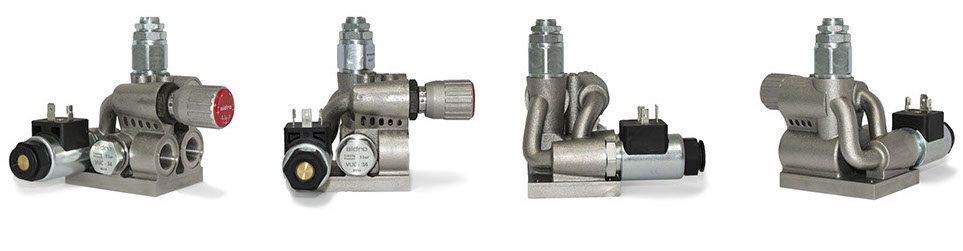

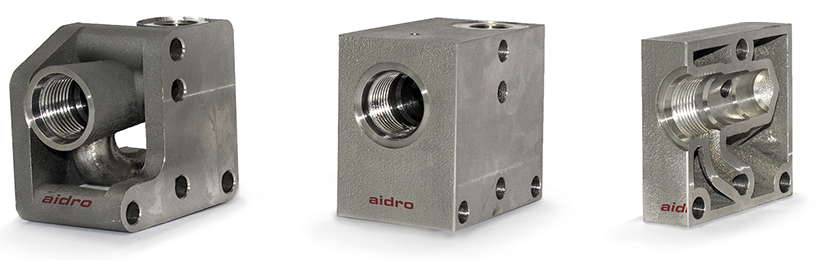

Hydraulic Valve Block

This is a 3D hydraulic valve block printed in stainless steel for controlling a single-acting cylinder.The traditional hydraulic block has been redesigned with a different and innovative design approach: put the valves in which it is necessary and connect the valves, as you wish, with the main objective to reduce the mass of the component whilst retaining its robustness.

Additive manufacturing is highly suited for the design and manufacture of manifolds due to its ability to build internal features and passageways. Our internal channels of the valve block are optimized to a better flow and space savings, while the potential for leakage is removed because auxiliary drillings are no longer necessary.

This 3D printed hydraulic block greatly meets the specific needs of customer.

3D printing advantages

→ Freedom to design

→ Possibility to produce complex geometries

→ High customization

→ Space saving

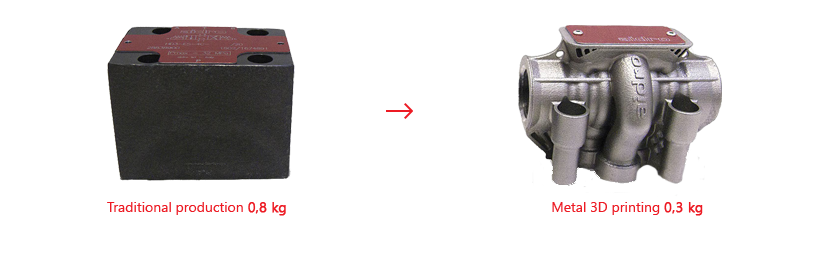

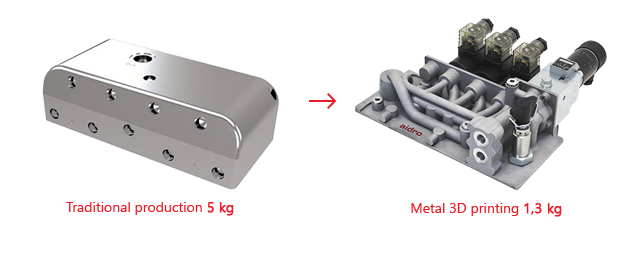

High pressure hydraulic manifold

In order to have a lightweight hydraulic valve, this stackable valve body has been redesigned to be 3D printed.The additive manufacturing allows a high reduction of the material used for the production, and the final weight of this valve has been reduced by 60% less.

With the addition of the pressure-reduction cartridge, we have created a direct operated pressure reducing valve in stainless steel. While, normally, the standard pressure reducing valves are made in steel zinc plated. Moreover, during the pressure tests, the 3D printed valve has demonstrated the same results as the traditional manufactured valves.

To test the materials variety offered by additive manufacturing, this hydraulic valve has been 3D printed in stainless steel, aluminum and in Maraging steel. The first material offers an high corrosion resistance, and it is widely used for special applications, such as oil&gas, yacht and naval. aluminum is lightweight and Maraging steel is known for possessing superior strength and toughness without losing malleability.

3D printing advantages

→ Optimized performances, thanks to curved channels and no more 90 degrees intersection angles

→ Good material properties (similar to metal bars)

→ Lightweight solutions

→ High pressure resistance (700 bar)

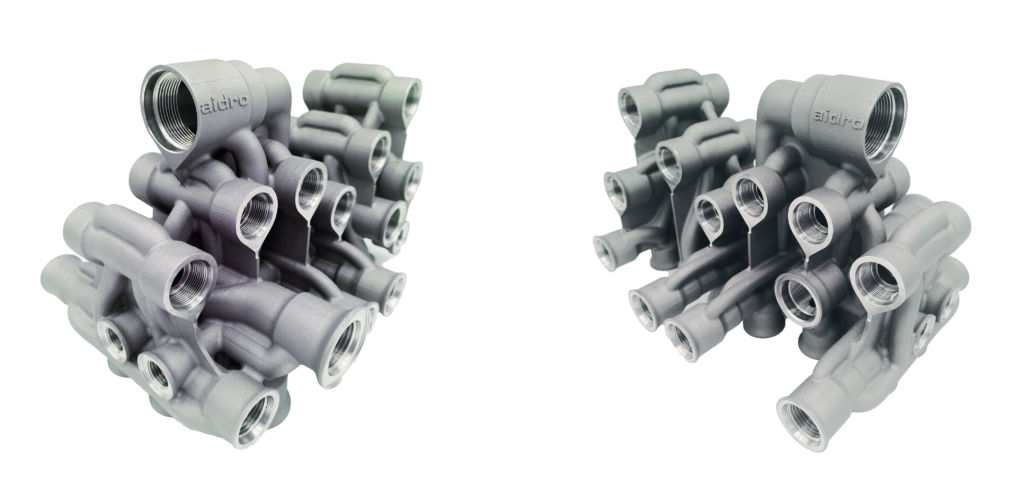

Bankable hydraulic manifold

With metal 3D printing the manifold can be multiplied providing more functionalities. The modular conception of valves allows to easy tailor the blocks to specific requirements.

3D printing advantages

→ Feasibility of geometric forms impossible with traditional machine

→ Ability to combine multiple parts into one

→ Better performance than the traditional manufacturing

Hydraulic Components

Hydraulic Spool

This spool has been redesigned in order to be 3D printed with new holes forms, such as oval holes and square holes.These shapes are impractical with traditional manufacturing, in particularly with CNC machining, while with additive manufacturing complex geometries are now feasible.

Indeed, with the new holes forms, our idea is to increase the passing area of oil inside the spool, allowing lower pressure drop. Therefore, the new design with additive manufacturing offers an higher performance.

Moreover, with the ability to build complex geometries, we have consolidated more components into one piece and our 3D printed spool is one single part. This allows to simplify the manufacturing process and reduce assembly time.

3D printing advantages

→ Availability of geometric forms impossible with traditional machine

→ Ability to combine multiple parts into one

→ Possible better performance than the traditional manufacturin

Pressure reducing valve body

In order to have a lightweight hydraulic valve, this stackable valve body has been redesigned to be 3D printed.The additive manufacturing allows a high reduction of the material used for the production, and the final weight of this valve has been reduced by 60% less.

With the addition of the pressure-reduction cartridge, we have created a direct operated pressure reducing valve in stainless steel. While, normally, the standard pressure reducing valves are made in steel zinc plated. Moreover, during the pressure tests, the 3D printed valve has demonstrated the same results as the traditional manufactured valves.

To test the materials variety offered by additive manufacturing, this hydraulic valve has been 3D printed in stainless steel, aluminum and in Maraging steel. The first material offers an high corrosion resistance, and it is widely used for special applications, such as oil&gas, yacht and naval. aluminum is lightweight and Maraging steel is known for possessing superior strength and toughness without losing malleability.

3D printing advantages

→ Weight reduction

→ Possible choice between high performing materials

→ Optimized performances

Overcenter valve

Overcenter valves (also known as counterbalance or load holding valves) are substantially a pilot assisted relief valve with an integral free flow check. They are normally used for load holding, load control or load safety, depending on the application and on the type of the valve. Tipically the relief setting will be 1.3 times higher than the maximum induced load. A variety of sizes, ranges and pilot ratios are available within Aidro catalogue.

3D printing advantages

→ Optimized flow paths for improved performances

→ The lowest weight in the class

→ Extreme stability on full working range

→ No auxiliary plugs

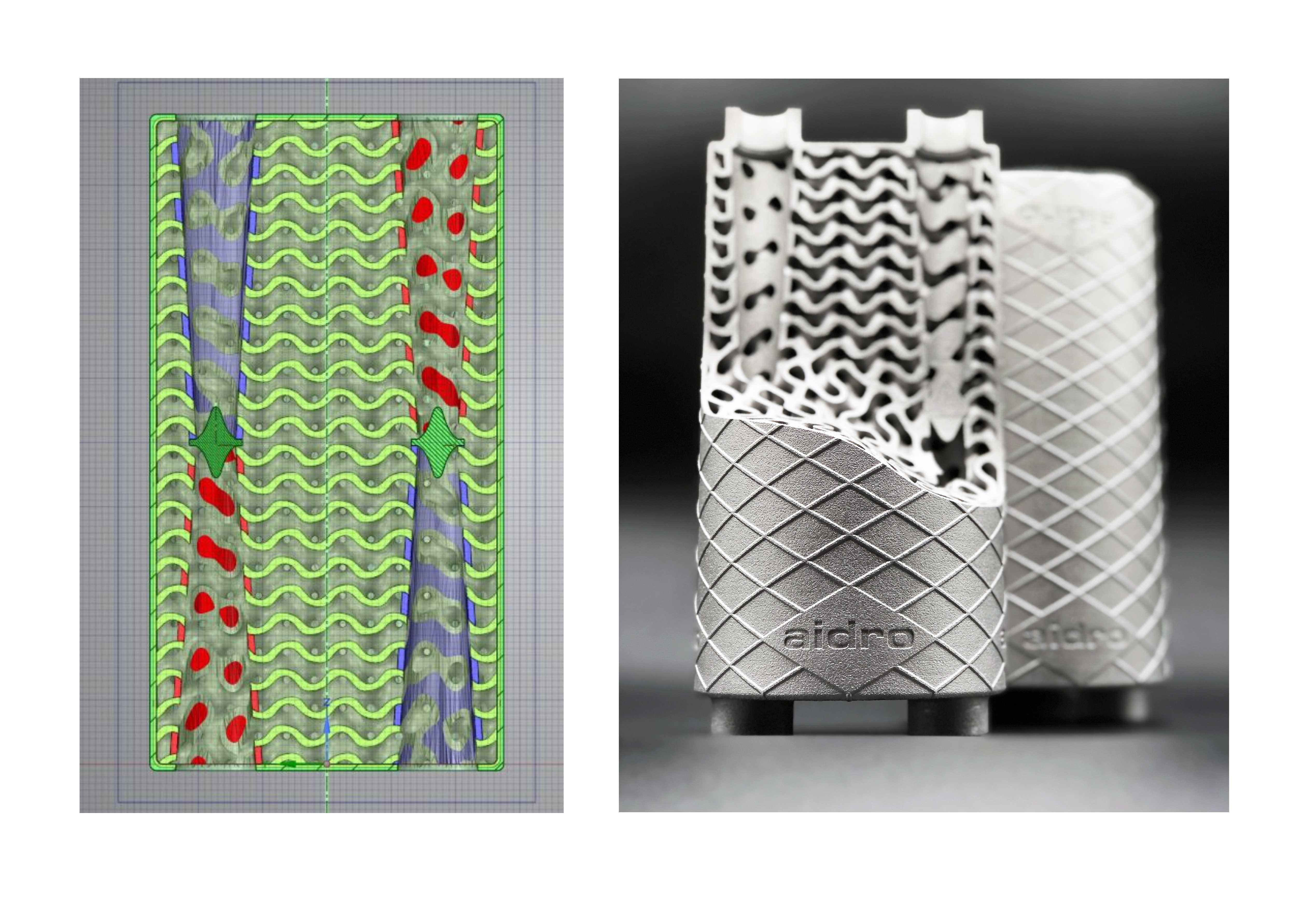

Heat Exchanger

Heat Exchanger

The 3D printed Heat Exchangers are available in a wide range of size and applications (water-oil, fluid-gas,…).

The design is customized depending on the needs of the system and evaluating the fluid dynamics.

The possibility of creating internal geometries that are impossible for conventional production methods, allows to obtain very compact heat exchangers suitable for the customer’s requests.

3D printing advantages

→ High performance in small size

→ Possibility to integrate multiple parts into one and avoid welding

→ Optimized performances

→ Weight saving till 85%

Aerospace Applications

3D printed scale model of Tilt Rotor Drive System

Aidro has contributed to the promotion of the Next Generation Civil Tilt Rotor Program by Leonardo Helicopters (NGCTR Clean Sky 2) through the creation of a small-scale 3D printed model of Tilt Rotor System.

We have used all our skills to design the NGCTR small-scale model and produce it using various technologies: additive manufacturing including metal Binder Jetting, Laser Powder Bed Fusion and Selective Laser Sintering, CNC machining, electronics, and a lot of creativity.

Scale 1:5 100+ parts

Design activities to scale the components and to engineer the mechatronic actuator

Materials: Aluminum AlSi10Mg, steel 316L, steel 17-4PH, Nylon PA12, carbon fiber

Very fast leadtime

Watch the video here

Energy, Oil & Gas, Maritime Applications

Pump System components

The Pump System has been designed by Aidro for Additive Manufacturing and in stainless steel (316L and 17-4 PH), using binder jetting and laser powder bed fusion technologies to create an innovative design and optimization project.

It is composed by:

→ Impeller (Ø 160 mm) – it is designed for Additive Manufacturing and it is one of the biggest part ever produced with Metal Binder Jetting technology. This impeller requires less post-processing and features high-quality, self-supported internal channels.

→ Volute Housing (Ø 240 mm and walls 1 mm thick) – it is designed with 360 degrees reinforcement ribs thanks to Additive Manufacturing, which provides lightweight, high performance and high-strength part.

→ Filter (Ø 120 mm and a 0.3 mm mesh) – it is produced with thin walls and reinforcing structures thanks to Additive Manufacturing, which provides lightweight and high-strength part. This filter is installed on the top of the pump housing for energy and oil&gas applications.

Every part of Pump System was internally machined.

Impeller

These Impellers (Ø 6 cm – Ø 10 cm – Ø 16 cm) have been designed for Additive Manufacturing with Metal Binder Jetting Technology.

They require less post-processing and features high-quality, self-supported internal channels.

Valves components

This Rotary Valves Bonnet has been re-designed for additive manufacturing and 3D printed in stainless steel 316L.

The improved internal paths and flow optimization lead to a higher performance valve bonnet among with a reduced weight of the part itself. The weight saving is particularly interesting for sub-sea applications in order to reduce the costs of transport and handling. On demand production and no tooling costs also bring advantage of AM in energy sector.

Courtesy of Valland

3D printing advantages

- → Avoiding welding and no more assembling tooling are required

- → On-demand production and fast spare parts

- → High reliability

- → Lower Carbon Footprint

R&D Projects

Research and Development

We are involved in many R&D projects on Additive Manufacturing:

– KYKLOS 4.0 OPEN CALL (Atilius Project): https://kyklos40projecteu/open-calls/funded-experiments-2/

– DREAM OPEN CALL (Euroclusters): https://clustercollaboration.eu/sites/default/files/profile-article/DREAM%20funded%20projects__1.pdf

– FF4EuroHPC: https://www.ff4eurohpc.eu

– 3DPPan: https://3dppan.eu

– CIM: https://cim40.com

– MICS Made in Italy Circolare e Sostenibile: https://www.mics.tech/progetti-bac/bjmi/

![]()

Other Projects

Watches

Our passion for art, complex challenges and mechanics pushes us to explore new sectors, such as watches and fashion, to exploit our skills in design and additive manufacturing, in order to create functional, harmonious and beautiful parts.

Additive Manufacturing technology is perfect for creating artistic shapes.

Aidro can design and 3D print custom-made watches, rings, jewelry and fashion accessories.

In the photo: the stainless steel 316L watch “Octopus” designed by Materiaggiunta Watches

Servofly T4/1

A custom-made device was produced to allow a person with disabilities to pilot a plane.

Without any structural modification, the aircraft cockpit was integrated with a “plug-and-fly” flight control system, made of aluminum using powder-bed laser fusion technology (LPBF or SLM). This tool was named “ServoFly T4/1“, and allows Mattia to fly an ultra-light aircraft with only one hand.

The electronic system was developed by Tecno Elettra Impianti S.r.l., one of the leading Italian companies in electrical wiring.

The mechanical tests were carried out by AeroClub experts from the Fano airport and Mattia’s training was followed by the Eagles Aviation Academy instructors.

More info here

Read the Press Release here

REGISTERED OFFICE

Via Camperio 9

20123 Milano (MI)

Italy

HEADQUARTERS

Via Prati Bassi 36

21020 Taino (VA)

Italy

+39 0331 960250

aidro@aidro.it

LATEST NEWS

© Copyright 2021. All Rights Reserved – Aidro s.r.l. a socio unico